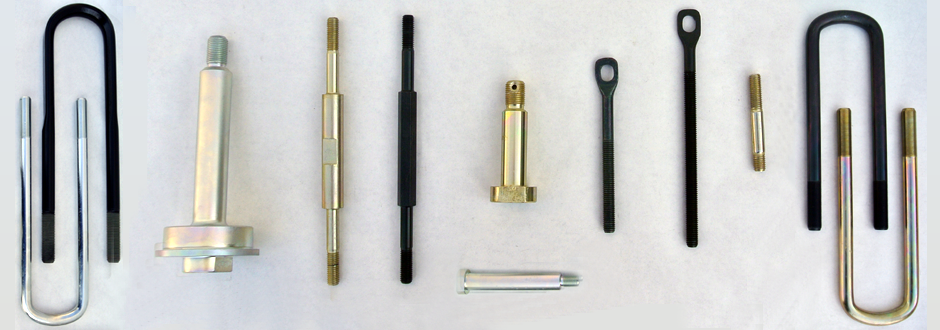

Manufacturing Facilities

With the expertise of over two decades, our state of Art Manufacturing Facilities along with the technological innovations in engineering has given us a competitive edge in the field of Cold & Hot forged High Tensile Fasteners. Major production machinery & equipment’s used in the manufacturing of fasteners include Multi-station automatic Cold / Hot bolt & nut Formers, Induction hardening machines, CNC machines, EDM machines, product optical & current eddy sorters ,Bolt makers , U bolt heating, forging, bending machines etc.

Design Technology

The success of a fastener depends on the quality of design, we at Imperial emphasize on technological Excellence and development consistently which makes us a class apart. Our highly motivated team of engineers uses the latest CAD software's to design & develop the tools used in making of fasteners. Our development team adds new products to our manufacturing range every year.

Testing

In order to ensure the best quality Fasteners, our manufacturing facilities are fully backed up with latest testing equipment’s. These include Rockwell hardness tester , Vickers hardness tester , Micro hardness tester, Eddy current sorters, Spectrometer, Universal tensile machine, Impact tester , Profile projector with DRDO System, Coating thickness tester, Salt spray test apparatus, Optical sorting machines , Optical pyrometer, Universal bevel protector, Magnetic crack detector , Metallurgical micro scope , Dew point controller (oxygen probe), Tri-roll gauges for thread checking, Torque wrench etc.